Printers print processed data in a form humans can read. To produce hard copy, the printer first receives electronic signals from the central processing unit. In an impact printer, these signals activate print elements that are pressed against paper. Newer, nonimpact printers use heat, laser technology, or photographic techniques to print output.

IMPACT PRINTERS. Impact printers come in a variety of shapes and sizes. Some print one character at a time, while others print a line at a time. Dot- or wire-matrix printers and daisy-wheel printers are the principal types of impact printers.

Dot-matrix (also called wire-matrix) printers are based on a design principle similar to that of a football or basketball scoreboard. The matrix is a rectangle composed of pins. Certain combinations of pins are activated to represent characters. For example, the number 4 and the letter L are formed by a combination of pins being pressed against paper. The dot combinations used to represent various numbers, letters, and special characters are shown below.

The quality of characters produced by a dot-matrix printer is determined by the resolution of the matrix used to produce the character. The more dots that can be printed in the matrix, the higher the quality of print. Near-letter-quality (NLQ) characters produced by dot-matrix printers contain more dots placed closer together. Most dot-matrix printers sold today have either 9- or 24-pin print heads. They print at speeds ranging from 80 characters per second in NLQ mode to 400 characters per second in draft mode.

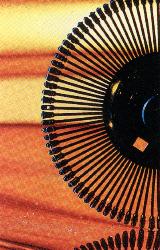

Daisy wheel printers use a daisy wheel, which is a flat disk with petal-like projections (see picture below).

Daisy wheels come in several type fonts that can be interchanged quickly to suit application needs. The daisy wheel printer offers high quality type and is often used in word-processing systems to give output a typewriter quality appearance. Daisy wheel printers can produce up to 3,000 characters per minute.

Types of line-at-a-time printers include print wheel, chain, and drum printers. A print wheel printer typically contains 120 print wheels, one for each of 120 print positions on a line (see picture below).

Each print wheel contains forty-eight alphabetic, numeric, and special characters. The wheel rotates until the desired characters move into the corresponding print position on the current print line. When all wheels are in their correct positions, a hammer drives the paper against the wheels and an entire line of output is printed. Printwheel printers can produce about 150 lines per minute, which makes them rather slow compared to other line-at-a-time printers.

A chain printer has a character set assembled in a chain that revolves horizontally past all print positions (see picture below).

The printer has one print hammer for each column on the paper. Characters are printed when hammers press the paper against an inked ribbon, which in turn presses against appropriate characters on the print chain. The fonts can be changed easily on chain printers, allowing a variety of fonts, such as italic or boldface, to be used. Some chain printers can produce up to 2,000 lines per minute.

A drum printer uses a metal cylinder with rows of characters engraved across its surface (see picture below).

Each column on the drum contains a complete character set and corresponds to one print position on the line. As the drum rotates, all characters are rotated past the print position. A hammer presses the paper against the ink ribbon and drum when the appropriate character is in place. One line is printed for each revolution of the drum, since all characters eventually reach the print position during one revolution. Some drum printers can produce 2,000 lines per minute.

NONIMPACT PRINTERS. Nonimpact printers do not print characters by means of a mechanical printing element that strikes the paper. Instead, a variety of other methods are used. Electrostatic, electrothermal, ink-jet, laser, and xerographic printers are some of these types.

An electrostatic printer forms an image of a character on special paper using a dot matrix of charged wires or pins. The paper is moved through a solution containing ink particles that have a charge opposite that of the pattern. The ink particles adhere to each charged pattern of the paper, forming a visible image of each character.

Electrothermal printers generate characters by using heat and heat-sensitive paper. Rods are heated in a matrix. As the ends of the selected rods touch the heat-sensitive paper, an image is created. Both electrothermal and electrostatic printers operate quietly. They are often used in applications where noise may be a problem. Some of these printers are capable of producing 5,000 lines per minute. The paper required for use in electrothermal printers, however, is expensive and in many cases cost prohibitive.

In an ink-jet printer, a nozzle is used to shoot a stream of charged ink toward the paper. Before reaching it, the ink passes through an electrical field that arranges the charged particles into characters. These printers can produce up to 12,000 characters per minute.

Laser printers combine laser beams and electrophotographic technology to create output images. A beam of light is focused through a rotating disk containing a full font of characters. The character image is projected onto a piece of film or photographic paper, and the print or negative is developed and fixed in a manner similar to that used for ordinary photographs. The output consists of high quality, letter-perfect images. The process is often used to print books. Laser printers, which can operate at speeds of up to 21,000 lines per minute, are often replacing the slower printers that have been used with word-processing systems in the past.

Xerographic printers use printing methods much like those used in common xerographic copying machines. For example, Xerox, the pioneer of this type of printing, has one model that prints on single 8½-by-11-inch sheets of plain paper rather than on the continuous form paper normally used. Xerographic printers operate at speeds of up to 4,000 lines per minute.

Nonimpact printers are generally faster than impact printers because they involve less physical movement. They offer a wider choice of typefaces and better speed-to-price ratios than impact printers, and their technology implies a higher degree of reliability because they use fewer movable parts in printing. The disadvantages of nonimpact printers include the special paper requirements and the poor type-image quality of some printers. Also, nonimpact printers cannot make carbon copies. Yet nonimpact printers can produce several copies of a page in less time than it takes an impact printer to produce one page with several carbon copies.

New print systems now on the market combine many features of the printing process into one machine. For example, collating, routing, hole punching, blanking out of proprietary information, and perforating may be performed. Some printers produce both text and form designs on plain paper, reducing or eliminating the need for preprinted forms. Furthermore, some laser and ink jet printers can also print in color.